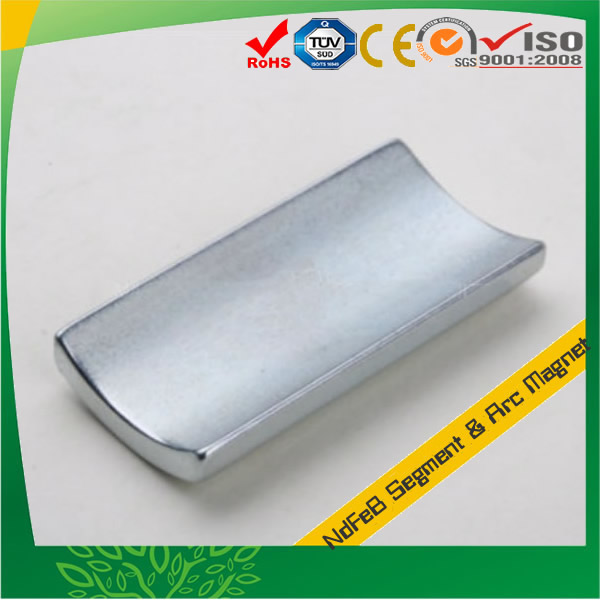

Zn Plated Sintered N50 Neodymium Magnet, Neodymium-Iron-Boron Segment Magnet, Segment Neodymium Magnet, Rare Earth Motor Customized Magnets China Manufacturer

Product Name: Zn Plated Sintered N50 Neodymium Magnet

Magnet ID:Arc-N50-Zn-6

+ Highest Energy of All Permanent Magnets

+ Moderate Temperature Stability

+ High Coercive Strength

+ Moderate Mechanical Strength

Our Superiority: Customized is Available!

* T/T, L/C, Paypal and other payment accepted.

* Orders of any size.

* Worldwide delivery. Fast Shipping.

* Quality and price guaranteed.

* Contact us to discuss your magnet needs.

Hangseng Magnetech Inc. (SUPERMAG, neoi) is your best source for the highest quality magnets, neodymium magnets, magnetic devices and expert application assistance for OEM, point-of-purchase, industrial and retail markets.

Neodymium-Iron-Boron Segment Magnet Some important properties used to compare permanent magnets are: remanence (Br), which measures the strength of the magnetic field, coercivity (Hci); the material’s resistance to becoming demagnetized, energy product (BHmax), the density of magnetic energy, and Curie temperature (TC), the temperature at which the material loses its magnetism. Neodymium magnets have higher remanence, much higher coercivity and energy product, but often lower Curie temperature than other types. Neodymium is alloyed with terbium and dysprosium in order to preserve its magnetic properties at high temperatures. The table below compares the magnetic performance of neodymium magnets with other types of permanent magnets.Some important properties used to compare permanent magnets are: remanence (Br), which measures the strength of the magnetic field, coercivity (Hci); the material’s resistance to becoming demagnetized, energy product (BHmax), the density of magnetic energy, and Curie temperature (TC), the temperature at which the material loses its magnetism. Neodymium magnets have higher remanence, much higher coercivity and energy product, but often lower Curie temperature than other types. Neodymium is alloyed with terbium and dysprosium in order to preserve its magnetic properties at high temperatures.[fusion_builder_container hundred_percent=”yes” overflow=”visible”][fusion_builder_row][fusion_builder_column type=”1_1″ background_position=”left top” background_color=”” border_size=”” border_color=”” border_style=”solid” spacing=”yes” background_image=”” background_repeat=”no-repeat” padding=”” margin_top=”0px” margin_bottom=”0px” class=”” id=”” animation_type=”” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”no” center_content=”no” min_height=”none”][12] The table below compares the magnetic performance of neodymium magnets with other types of permanent magnets.

Magnet Br (T) Hci (kA/m) BHmax (kJ/m3) TC (°C) TC (°F)Nd2Fe14B (sintered) 1.0–1.4 750–2000 200–440 310–400 590–752Nd2Fe14B (bonded) 0.6–0.7 600–1200 60–100 310–400 590–752SmCo5 (sintered) 0.8–1.1 600–2000 120–200 720 1328Sm(Co, Fe, Cu, Zr)7 (sintered) 0.9–1.15 450–1300 150–240 800 1472Alnico (sintered) 0.6–1.4 275 10–88 700–860 1292–1580Sr-ferrite (sintered) 0.2–0.4 100–300 10–40 450 842[/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]