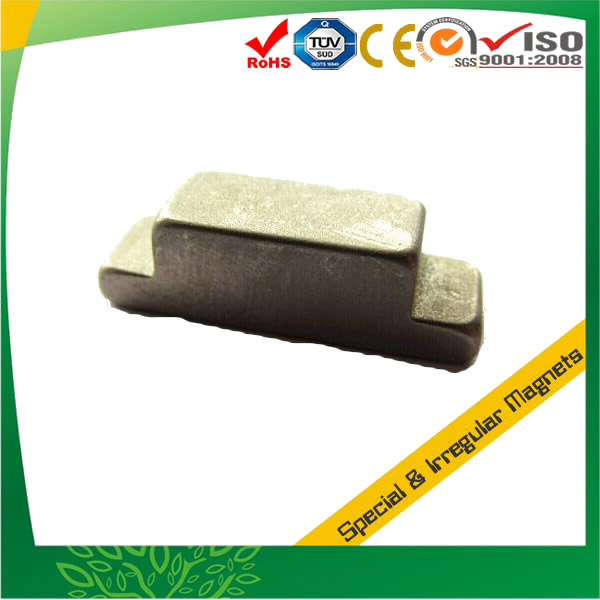

Arc Countersunk Hole Neodymium Magnet, N50 Sintered NdFeB Segment with Countersink, Neodymium-Iron-Boron Segment with Countersunk, Rare Earth Segment Countersunk Magnet

Product Name: Arc Countersunk Hole Neodymium Magnet

Model No:NCS-3-N50

Specifications:

1. Powerful permanent pot magnet

2. High quality & best price

3. High working temperature

4. Good corrosion resistance

Original Manufacturer:HangSeng Magnetech

Solution:Customized your required material, size, coating, shape, grade, pull force and woking temperature

Origin:Ningbo, Zhejiang, China

Supply Ability:50000pcs/day

Certification:SGS,TUV,ISO9001,ROHS,TS16949

Applications:magnetic holding, lifting, antenna Mounting, positioning, retrieving and much more.

HANGSENG Magnetic Technologies is the leading worldwide source for magnets and magnetic assemblies. We supply high integrity, mission critical assemblies for use in aerospace & defense, oil and gas, automotive, medical, energy storage, and consumer and industrial applications. For over five decades, we have engineered solutions for our customers by providing both magnets and precision assemblies made to print or co-developed to complete their projects.

From the straight-forward to the most complex combination of magnetic and non-magnetic materials, our advanced assembly services offer unparalleled expertise, quality and affordability. Our experienced team of Engineers and Production Workers located at all of our worldwide locations, are able to offer you a wide range of capabilities for your magnetic needs.

Global Service and Support Sintered NdFeB Magnets N35EH

HSMAG’s worldwide team of Engineers, Designers and Project Managers direct the production of assemblies at our facilities in Rochester, New York; Lupfig, Switzerland; Sheffield, England and NINGBO, Shenzhen, China. We can match our strengths and locations to meet your project needs.

Capabilities

Our manufacturing range covers large volume production of systems for the automotive industry as well as small series of high tech aerospace products and individual large assemblies for electrical machines. Some examples of HSMAG’s capabilities are:

EDM

ID slicing and grinding

In house machining of hubs, rotors, cylinders, sleeves

Magnetic and thermal stabilization of magnets

Rotor dynamic balancing

Wraptite carbon fibre sleeving

Serializing

Magnetic characterization

Magnet fabrication from a large stock of a Recoma samarium cobalt and neodymium in a variety of grades, alnico and ceramic or hard ferrite.This includes magnets for TWT systems.

System Integration