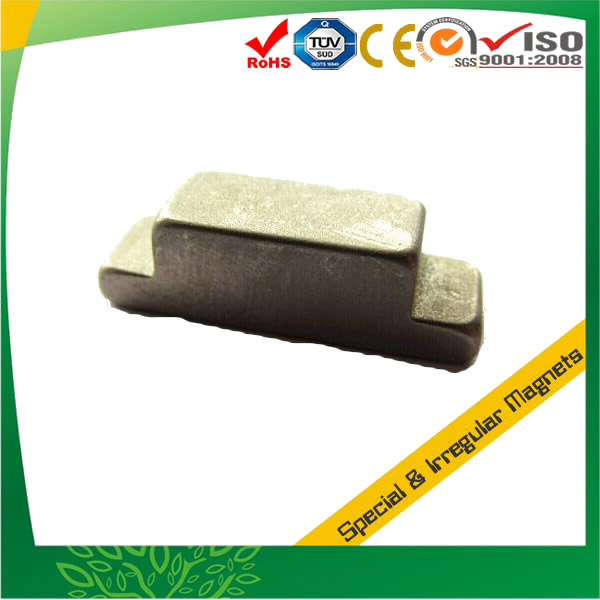

High Energy Neodymium Rectangular Custom Magnet, Stepped Rare Earth Sintered Neodymium Stepped Magnets, Custom made podium shape special irregular magnets, High Coercive Strength Custom Permanent Magnets Product Name: High Energy Neodymium Rectangular Custom Magnet Magnet ID: Neodymium-CMN42-02 + Highest Energy of All Permanent Magnets + Moderate Temperature Stability + High Coercive Strength + Moderate Mechanical […]